Carbon Doped Tungsten Oxide Nanorods NO2 Sensor Prepared by Glancing Angle RF Sputtering

Nanostructures such as nanowires, nanorods, nanotubes of metal oxide semiconductor (MOS) materials have recently attracted monumental interest in gas-sensing applications because of their excellent performances owing to their large surface to vol-ume ratio, lower electron recombination rate and high stability. Among various MOS materials, tungsten oxide (WO3) is a highly promising candidate due to its fast response with high sensitivity toward NOx.

Glancing angle depositio (GLAD) technique is a relatively new method for fabrication of well-ordered and sophisticated nanostructures i.e. nanorods, nanoblade and zigzag nanocolumns. It is a modified physical vapor deposition process, in which substrate surface is rotated and tilted to an angle greater than 80° with respect to the normal of substrate surface or less than 10°with respect to the direction of vapor flux. The vapor molecules directed to the substrate will experience shadowing and limited surface diffusion condition leading to the formation of isolated nanostructures. With this technique, the shape, size and density of nanostructures can be well controlled by deposition parameters such as deposition angle, operating pressure, substrate temperature, deposition power, and so on. In this report, carbon-doped WO3 nanorods is fabricated by GLAD technique using RF magnetron sputtering and investigated for NO2 gas sensor application. In addition, its performances are comparatively studied with that of the undoped ones.

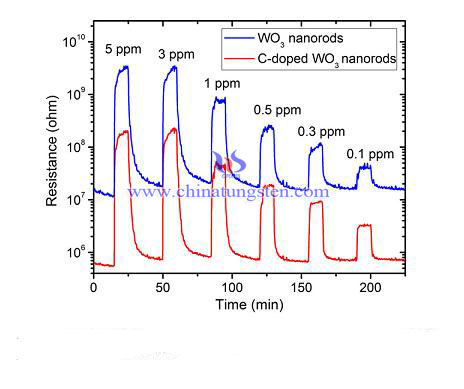

Carbon-doped and undoped WO3 nanorods gas sensors have successfully been fabricated by the GLAD technique with RF magnetron sputtering. By this technique, the vertically well-aligned homogeneous tungsten oxide nanorods with very low defect were achieved over a large area. It was found that carbon doping does not change any crystalline structure but increases the grain size and accelerates the nanorods growth leading to relatively high aspect ratios as compared to the undope one. The fabricated carbon-doped WO3 nanorods sensor exhibits high response and selectivity to NO2 at the concentration range of 0.5–5 ppm at an optimum operating temperature of 250℃. In addition, the carbon-doped sensor still works well for NO2 detection at lower operating temperature of 150℃ due to the decrease of activation energy and alteration of the depletion layer. Therefore, carbon-doped well-ordered WO3 nanorods with improved NO2 gas-sensing performances in terms of response, response time, selectivity and operating temperature has been realized. Moreover, this technique offers distinct advantages over other methods such as high productivity, simplicity and low cost for well-ordered nanostructure construction.

If you have any other question or inquiry of tungsten oxide, please feel free to contact us through the following methods:

Tel.: +86 592 5129696/86 592 5129595

Fax: +86 592 5129797

评论

发表评论