How Impurities Affect Tungsten Powder Production

In the production of tungsten metal by powder metallurgy, the chemical purity is especially important because the subsequent sintering process can only be achieved by evaporation to a certain extent.

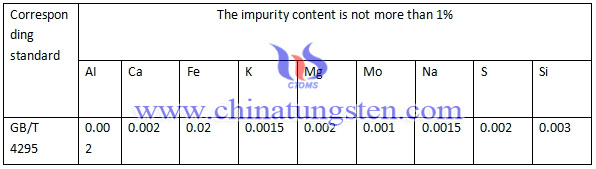

With the development of industry, the requirement of the purity of tungsten powder is increasing day by day, because the impurities left after the sintering of tungsten powder have a great influence on the processability and properties of the final products.

In the production process of tungsten concentrate to tungsten powder, tungsten purity is constantly improved, and the purity is high when APT is made. However, when APT is processed into tungsten powder, the purity decreases. Why?

According to the study, tungsten powder impurities mainly from the material and the reduction of the furnace tube and metal boat contact, as a result, the impurity content is increased, and these impurities are present in a heterogeneous form, the result is the increase in impurity content. These impurities exist in heterogeneous form, forming a region with a high concentration of impurities, and if the size of these cells to a certain extent, it may become the source of sintering defects.

There are mainly three kinds of impurities in the reduction process of tungsten powder:

The first kind of impurity is the alkali metal meter, which is a volatile element or compound in hydrogen, regardless of the amount of it, which causes the adverse effects of particle growth; In the process of reduction, tungsten powder may also be adsorbed, which is the biggest enemy to prepare ultrafine tungsten powder.

The second kind is represented by Fe, S and As, mainly from the contact with reduction furnace or metal equipment. When the content is low, it has no great influence, but when the content increases to a certain extent, the particle size of tungsten powder will become larger;

The third kind, represented by Al, Mo and P, can inhibit the growth of tungsten powder particles. A little amount can be used to assist the preparation of ultrafine tungsten powder. But from the purity of tungsten powder requirements, the lower the better.

In addition, the preparation of tungsten powder is also affected by some trace elements, such as tungsten oxide reduction process of excessive moisture, the process of reducing the concentration of water vapor in the furnace, will lead to tungsten powder particles and particle size distribution uneven, it can add appropriate amount of rare earth elements, can play a similar role in Al, effectively inhibit the hydrogen reduction process of tungsten powder particles grow.

If you have any inquiry of tungsten, please feel free to contact us:

Tel.: +86 592 5129696/+86 592 5129595

Fax: +86 592 5129797

Scan QR code of Chinatungsten Wechat platform to follow up the daily latest price and market of tungsten, molybdenum and rare earth.

评论

发表评论