Tungsten Oxide Thermal Metamaterial Innovation Helps Bring Waste-heat Harvesting Technology to Power Plants

An international research team has used tungsten oxide thermal metamaterial to control the emission of radiation at high temperatures, an advance that could bring devices able to get efficient waste-heat harvesting technology from power plants and factories. Roughly 50 to 60 percent of the energy generated in coal and oil-based power plants is wasted as heat. However, thermophotovoltaic devices that generate electricity from thermal radiation might be adapted to industrial pipes in factories and power plants, as well as on car engines and automotive exhaust systems, to recapture much of the wasted energy. In new findings, researchers demonstrated how to restrict emission of thermal radiation to a portion of the spectrum most needed for thermophotovoltaic technology.

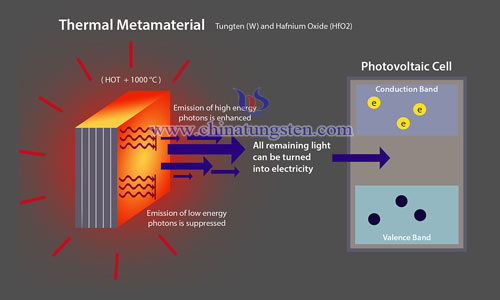

"These devices require spectrally tailored thermal emission at high temperatures, and our research shows that intrinsic material properties can be controlled so that a very hot object glows only in certain colors," said Zubin Jacob, an assistant professor of electrical and computer engineering at Purdue University. "The main idea is to start controlling thermal emission at record high temperatures in ways that haven't been done before." The thermal metamaterial – nanoscale layers of tungsten oxide and hafnium oxide – was used to suppress the emission of one portion of the spectrum while enhancing emission in another.

The basic operating principle of a photovoltaic cell is that a semiconducting material is illuminated with light, causing electrons to move from one energy level to another. Electrons in the semiconductor occupy a region of energy called the valence band while the material is in the dark. But shining light on the material causes the electrons to absorb energy, elevating them into a region of higher energy called the conduction band. As the electrons move to the conduction band, they leave behind "holes" in the valance band. The region between both bands, where no electrons exist, is called the band gap.

Future research will include work to convert heat radiation from a thermal metamaterial to electron-hole pairs in a semiconducting material, a critical step in developing the technology. The thermophotovoltaic technology might be ready for commercialization within seven years, Jacob said.

If you have any inquiry of tungsten oxide, please feel free to contact us:

Tel.: +86 592 5129696 +86 592 5129595

Fax: +86 592 5129797

评论

发表评论