Nanoporous Tungsten Oxide Making Flexible Memories Device at Room Temperature

Researchers in the US and Korea say they have developed a new way to make a flexible, resistive random access memory (RAM) device in a room-temperature process – something that has proved difficult to do until now.

The device, which is based on nanoporous tungsten oxide, is a bipolar switch and has a high on/off current ratio of more than 105. It can also be bent and unbent over 103 cycles without suffering any significant loss in performance.

For more than half a century, silicon-based complementary metal-oxide-semiconductor (CMOS) transistors have been the uncontested leaders in the electronics memory industry. However, such memory is reaching its fundamental limits because it is difficult to make CMOS transistors any smaller using current technology – something that will be a drawback for next-generation nanomemory applications. These memories are also quite expensive to assemble and suffer from relatively low switching speeds (of a few microseconds).

Researchers have thus been busy looking for other oxide-based alternatives to CMOS transistors and the most promising of these appear to be the transition metal oxides thanks to their excellent resistive switching characteristics, flexible stoichiometry and compatibility with CMOS processes. Tungsten oxides (WO3-x ) are one of the best transition metal oxides in this context, but the problem is that these materials need to be annealed at high temperatures or plasma treated to improve their quality. Such treatments are not compatible with those used to produce flexible electronics on plastic substrates.

Electrochemical Anodic Treatment

A team led by James Tour of Rice University in the US recently developed a room-temperature electrochemical anodic treatment to convert metal thin films to metal oxide layers. The researchers have now prepared a nanoporous WO3-x layer on a 175 µm flexible PET substrate using its technique. Anodization is an electrochemical etching process that creates a porous oxide layer on the surface of a metal. The process is called anodizing because an anodic current or voltage is applied to the working electrode in an electrochemical cell.

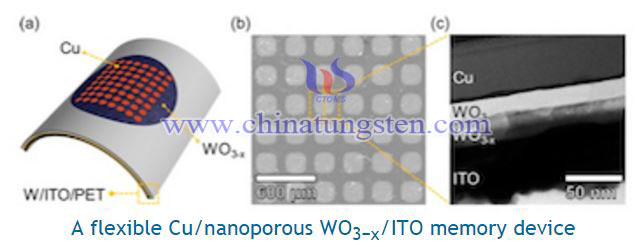

The nanoporous WO3-x layer thus produced can be used as the active layer in a RRAM device and the researchers have demonstrated this by making a flexible copper/nanoporous WO3-x /ITO memory device on a PET substrate. The device is bipolar with an on/off current ratio of more than 105. What’s more, it continues to operate after being bent and unbent over 1000 times without suffering from any serious switching failure.

If you have any inquiry of tungsten oxide, please feel free to contact us:

Tel.: +86 592 5129696 +86 592 5129595

Fax: +86 592 5129797

评论

发表评论