Preparation of Nano Tungsten Trioxide Gas Sensing Film by Gas Phase Method

Nano tungsten trioxide is a typical N-type semiconductor gas sensing material, it has a large surface area, stable chemical properties, a wide band gap, a variety of toxic gases have good sensitivity, can effectively improve gas sensor sensitivity and response speed, is a good gas-sensitive film material.

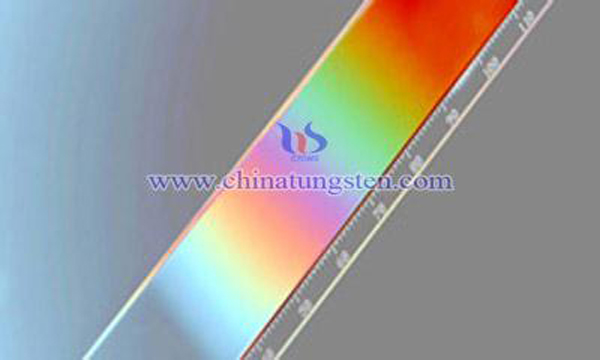

The preparation and synthesis of nano tungsten trioxide thin film by gas phase method is mainly to convert the synthesized tungsten trioxide crystal into the state of gas phase of tungsten trioxide through steps of sublimation, evaporation and decomposition. By setting the experimental conditions, the tungsten trioxide is transformed into tungsten trioxide saturated vapor. Finally, as the temperature decreases, saturated steam will crystallize in cold to grow as nanostructured tungsten trioxide crystals.

The preparation of nano tungsten trioxide gas-sensitive film gas method includes two kinds of chemical and physical methods.

Chemical vapor deposition (CVD) principle is the use of gas raw materials in the gas phase to form a chemical reaction and after two stages of nucleation and growth of the final preparation of the desired products (such as films, particles, whiskers). The use of chemical vapor deposition is also a method of preparing WO3 films. W(CO)6 as raw material, heated to 60 ~ 100 ℃, generate steam, and then N2 carrier gas generated steam at 300cm3min-1 flow rate of loading, W(CO)6 in the reaction chamber decomposition, the WO3 deposition to the base. Chemical vapor deposition (CVD) has the characteristics of continuous process, controllable and high purity. At the same time, multi-functional composite films can be prepared continuously by this method.

Physical vapor deposition (PVD) includes many basic particle growth processes such as the nucleation of nanostructured tungsten trioxide particles and the growth and aggregation of WO3 nucleus. The method of completing the particle transfer and transferring the basic unit to a specific location through a basic physical process is called a physical vapor deposition method. The typical method is vacuum evaporation, the principle is under high vacuum or high purity inert atmosphere (Ar, He), the evaporation of material under vacuum heating, WO3 vapor condensation in an inert gas medium to form a thin film. In recent years, they have also developed electron beam evaporation, ion beam assisted evaporation technology.

Regardless of the chemical deposition method or the physical deposition method to prepare the tungsten trioxide film, the prepared film has the advantages of high purity, stable performance and even particle distribution, and is suitable for the preparation of low melting point and single component films, but the shortcomings are also obvious, that is, the high cost, the preparation conditions are strict, the process is complex, and it is not suitable for large area preparation.

评论

发表评论