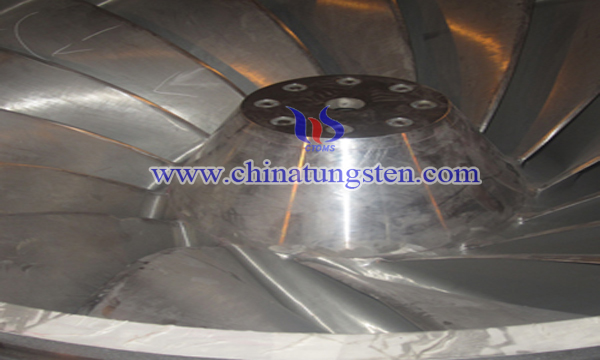

Tungsten Carbide / Cobalt Sprayed Coating

Thermal sprayed tungsten carbide / cobalt cermet is widely used in aerospace, metallurgy, machinery and other fields due to its good hardness and toughness.

Thermal spraying (spray welding), surfacing and other processes are gradually becoming the commonly used alloy, steel material anti-wear and surface corrosion technology measures. Tungsten carbide / cobalt thermal spraying technology has a simple process compared with other thin film and coating preparation technology, the coating and substrate have a wide range of selection, a large range of coating thickness, high deposition efficiency and easy to form composite coating.

The wear resistance of alloy is a systematic engineering problem. The material is only an important aspect to measure the grindability. In addition, it is also related to the stress state, surface structure, lubrication conditions, environmental temperature and other factors. The characteristics of thermal spraying powder vary with the milling process. The usual preparation methods include sintering crushing method, agglomeration sintering method, mixing method, coating method, melting method, etc..

The powders prepared by sintering method are generally rough and angular shape, and the particles are compact inside. A large number of WC particles are distributed in the Co matrix, and a single WC particle is combined with the Co matrix. Agglomeration sintering is a kind of solid aggregate particles containing organic binder in the liquid medium. The WC powder and Co powder are mixed evenly and spray drying is formed. Finally, the heat treatment is carried out.

The mixed powder prepared by WC and Co phase, the WC particles were loose co polymerization together; coating on the surface of WC particles is coated with cobalt form; melting method is made by crushing and melting casting method, powder particle size is generally big.

With the progress of nanotechnology, a new spraying process cold spraying has been developed in recent years. The nanostructured WC/Co coating prepared by cold spraying has no negative effect on decarburization, there is no porosity, and there is no gap and crack between the matrix and it has good bonding property. Cold spraying is a 100% solid state process without particle melting, which can solve the problems of decarburization, phase transformation and re solidification of nano coating melt particles during the conventional process.

If you have any inquiry of tungsten, please feel free to contact us:

Tel.: +86 592 5129696/+86 592 5129595

Fax: +86 592 5129797

Scan QR code of Chinatungsten Wechat platform to follow up the daily latest price and market of tungsten, molybdenum and rare earth.

评论

发表评论