Ultrafine Tungsten Powder Preparation -- High Energy Ball Milling

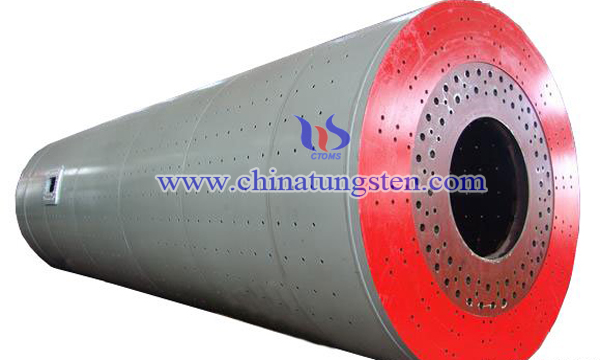

High energy ball milling method is used in low temperature, in the protective atmosphere, by using the rotation or vibration of the ball mill.

The hard sphere is subjected to strong impact, grinding and stirring, and the metal is crushed into nanometer particles. At present, high energy ball milling mainly uses vibrating ball mill, planetary ball mill and stirred ball mill to prepare nanometer powder.

In the nano structure formation mechanism study, that high energy ball milling is a process in which the particle circulation shear deformation, in this process, a large number of lattice defects ever produced within the great grain particles, leading to the re-combination of particles in the grain boundary. In the system of cells, the formation of nanocrystals is only the evolution of structures under mechanical driving. In the multivariate system, low temperature solid state reaction components will occurred during ball milling grinding, crushing, cold welding effect and mechanical effect, the grain size decreased with the increase of milling time, and the strain increased with the increase of milling time.

In the process of ball milling, due to the repeated deformation of the sample and the defect density reached the critical value in the local strain band, the grain began to break, and the process continued to repeat, and the grain was refined until the nanostructure was formed.

Some scholars have shown that metal tungsten powders with grain size 5nm can be prepared by high energy ball milling. The main factors affecting the ball mill technology are: raw material characteristics, milling time, ball mill media, ball material ratio, ball mill atmosphere.

High energy ball milling is an important method for preparing ultrafine tungsten powder. The preparation of nano tungsten powder with high yield, simple process and equipment, making the powder fine grain size and other advantages, is a promising technology in recent years has attracted more and more attention of materials scientists.

The main disadvantage is that the ball milling process will introduce impurities to make the tungsten powder contaminated, and the resultant powder is easy to agglomerate and not easy to disperse, and the energy consumption is higher. Therefore, this method is more suitable for the preparation of powder with little requirement of purity.

If you have any inquiry of tungsten, please feel free to contact us:

Tel.: +86 592 5129696/+86 592 5129595

Fax: +86 592 5129797

Scan QR code of Chinatungsten Wechat platform to follow up the daily latest price and market of tungsten, molybdenum and rare earth.

评论

发表评论