Ultrafine Tungsten Powder Preparation -- Hydrogen Reduction Method

The hydrogen reduction method of tungsten oxide, is a very complex physical and chemical processes, including chemical conversion, phase transformation, solid diffusion and so on.

The process generally is: tungsten oxide, hydrogen reduction, sifting, blending, tungsten powder. The reaction pathway of tungsten oxide reduction process is different, and the reaction rate is different. However, in order to obtain the best indicators, WO2 should be avoided in the reaction process to achieve the direct reduction of ultrafine tungsten powder from blue tungsten or purple tungsten. Although the quality of blue tungsten or purple tungsten is very important, other details should not be neglected. The key to obtain the desired effect is to master the key parameters such as temperature, humidity, operation and impurities.

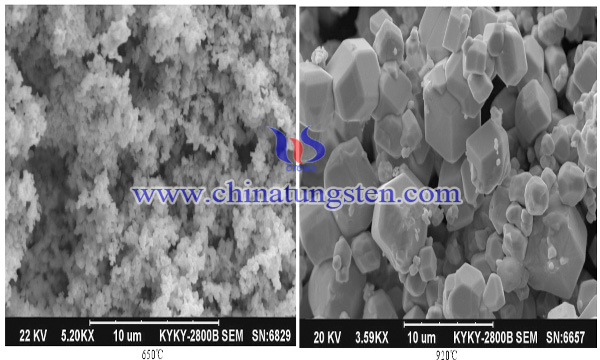

1. Temperature is the key factor to determine the preparation of ultrafine tungsten powder. The production has proved that, when the temperature is greater than 800, faith particle size of blue tungsten or purple tungsten began to fluctuate, the higher the temperature is, the reduction reaction will experience intermediate stage of WO2, WO2 is easy to sinter and re-crystallization at high temperature, which leads to the thickening of tungsten powder. Therefore, in industrial production, the total effect of elevated temperature on particle size is to thicken the W powder.

2. Humidity is the main factor affecting the preparation of ultrafine tungsten powder: Because tungsten oxides form WO2 (OH)2 with water vapor, this compound has high vapor pressure at 500~700 °C, H2 will be reduced in the reduction product, so that the particles become coarse. The main method of controlling humidity is to control the hydrogen flow in the reduction furnace, In general, it takes more H2 flow than ordinary tungsten powder to remove water vapor to prevent WO2 generation.

3. The amount of loading will also affect the size of the reduced tungsten powder. When the loading amount is large, the thickness of the material layer increases, which is not conducive to the diffusion of water vapor during the reduction. The tungsten oxide and water vapor have a greater chance of action, thus causing the powder to be thickened. The larger the loading capacity, the thicker the material layer, the coarser the size of the tungsten powder produced.

4. The influence of impurities on the particle size of tungsten powder is also very large. The impurities of tungsten powder are mainly three kinds: alkali metals Fe, S and As, regardless of the metal content, all of which cause the adverse effects of particle growth; The second kind, represented by Fe and AS, has no great influence on its content, but when the content increases to a certain extent, tungsten powder will grow; The third kind, represented by Al, Mo and P, can inhibit the growth of tungsten powder particles.

5. Hydrogen reduction reduces the pre-reduction of tungsten oxide in dryer hydrogen, which facilitates the refinement of tungsten powder; Reverse hydrogen reduction is the usual way to pass hydrogen. It makes the humidity of hydrogen higher at the beginning of the reduction process, and then reduces the particle size of the tungsten powder after reduction.

It is worth mentioning that, in the production process, the purple tungsten because of its special pore structure, which has good air permeability, can rapidly discharge water vapor from the reducing atmosphere, so the influence of particle size by boat loading weight and flow rate of hydrogen is very small. Compared to blue tungsten, purple tungsten is the best raw material for the production of ultrafine tungsten powder.

If you have any inquiry of tungsten, please feel free to contact us:

Tel.: +86 592 5129696/+86 592 5129595

Fax: +86 592 5129797

Scan QR code of Chinatungsten Wechat platform to follow up the daily latest price and market of tungsten, molybdenum and rare earth.

评论

发表评论