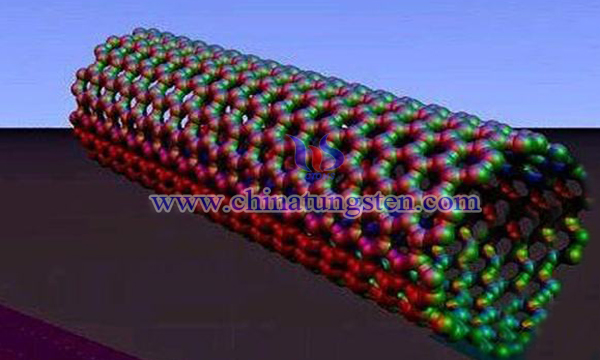

Carbon Nanotube Supported Platinum Electrocatalysts Coated with Titanium Tungsten Oxide

Carbon supported platinum catalysts are regarded as ideal fuel cell catalysts. However, the interaction between the carbon carrier and platinum is weak, the carbon carrier is easy to corrode. The nano platinum particles can easily migrate on the surface of the carrier, grow up and even lose, which leads to the degradation of the catalyst activity, and eventually leads to the shorter service life of the fuel cell.

In view of the disadvantages of poor stability and activity of existing fuel cell cathode catalysts, some scholars have used sol-gel method to evenly coat titanium tungsten oxide on the surface of carbon nanotubes, and then heat treatment to form titanium tungsten with high crystallinity and high electrical conductivity. The oxide coating, and thus the platinum catalyst, its main process is as follows:

(1) 1 gram of carbon nanotubes, adding 160 ml of concentrated nitric acid, reheating for 3 hours, cooling, diluted by ultra pure water, filtering out the supernatant, centrifuging and washing, drying, and grinding the purified carbon nanotubes.

(2) The mass ratio of 1: 2.5: 1 was called the purification of carbon nanotubes, butyl titanate and sodium tungstate, respectively, according to the volume ratio of 1: 0.2: 0.008, ethanol, ammonia and hydrogen peroxide respectively, of which the concentration of ammonia water was 28%, the mass concentration of the hydrogen peroxide solution was 30%, and the carbon nanotubes were dispersed in the anhydrous ethanol, and the carbon nanotubes were added to the anhydrous ethanol. The dispersion of n-butyl titanate in carbon nanotubes was obtained by ultrasonic stirring for 40 minutes. Sodium tungstate was dissolved in the ammonia water and added to the hydrogen peroxide solution. The ultrasonic oscillation was 15 minutes, and sodium tungstate solution was obtained. The sodium tungstate solution was slowly dripped into the above carbon nanotube titanate dispersion solution. After stirring reaction for 48 hours, the drying was dried. The amorphous titanium tungsten oxide coated carbon nanotube was coated, and the amorphous titanium tungsten oxide coated carbon nanotube was calcined at 650 C in nitrogen or argon atmosphere for 2 hours, cooling to room temperature, washing two times and washing for two times, drying and grinding to obtain the titanium tungsten oxide coated carbon nanotube.

(3) The mass ratio of 1: 1.1: 0.76: 10 was called titanium tungsten oxide coated carbon nanotubes, chloroplatinated acid, citric acid three sodium and sodium borohydride, and the obtained titanium tungsten oxide coated carbon nanotubes were dispersed in ethylene glycol, and ultrasonic stirring for 40 minutes, forming a mass concentration of 3 mg / ml of titanium tungsten oxide coated carbon nanotube dispersions. Then chloroplatin was slowly added to the titanium tungsten oxide coated carbon nanotube dispersions, stirring for 6 hours, and then adding sodium citrate three for 4 hours. Then the sodium hydroxide solution with mass concentration of 5% was adjusted to pH value to 9, and then slowly added to sodium borohydride and stirring for 4 hours, and then centrifuged, washed, washed, vacuum and vacuum. Titanium and tungsten oxide coated carbon nanotube supported platinum electrocatalysts were obtained by drying and grinding.

Titanium tungsten oxide coated carbon nanotube platinum electrocatalysts can be applied to fuel cells with proton exchange membranes as electrolytes, such as hydrogen oxygen proton exchange membrane fuel cells, direct methanol fuel cells and other gas electrodes. It can also be used in various spacecrafts, portable electronic devices, such as cameras, notebook computers, electric toys, etc.

评论

发表评论