The Milling Guide Refinement of Tungsten Trioxide

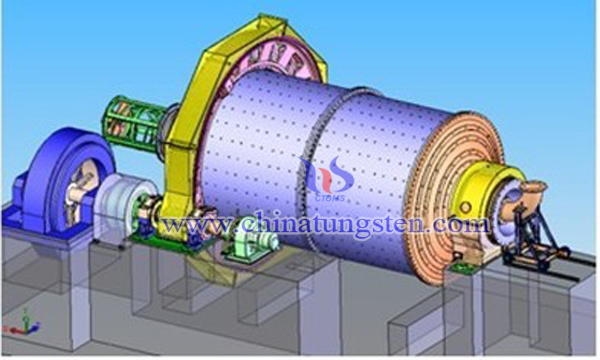

Ball mill is a fine equipment used in industry and can also be used for mixing.

The ball mill is composed of a cylinder and sphere, its working principle is when the cylinder rotates, installed in the cylinder body and the grinding body in grinding by centrifugal force and friction force with the cylinder to rotate to a height, and then automatically fall, the material in the cylinder impact and the grinding and grinding material.

The main factors affecting the efficiency of the ball mill are the speed of the ball mill, the quantity of the ball, the amount of water and electrolyte, the time and the loading. The normal milling time is about 24-72 hours, and the length of the ball milling time directly affects the quality of the ball milling product. Generally speaking, coarse grained material is easier to grind to coffee, and the time is shorter. However, the milling time of gal material to cut below is usually prolonged by several times or longer. However, with the prolongation of ball milling time, the cost of ball consumption and energy consumption will increase correspondingly, and the production capacity of the mill is decreased. Therefore, the appropriate ball milling time must be determined in the actual production.

In the process of ball milling, the ratio of solid to liquid is also a critical process parameter. During the process of mechanical milling, the solid liquid ratio, the shape and size of particles, and the interaction between particles will affect the rheological properties of slurry. The solid-liquid ratio is too low, medium ball received buoyancy, it will reduce the quality of the effective volume, the impact effect is bad, being a medium ball impact the opportunity will be less, so the production efficiency is low, high solid-liquid ratio is opposite, so too high or too low is not conducive to the refinement of tungsten trioxide.

The size of the material ratio directly determines the ball milling fineness, energy consumption, ball consumption and so on. In general, the larger the ratio of the material to the material, the more the relative quantity of the medium, the increase of the impact and the number of shearing of the material, and the enhancement of the effect of refining the crushing.

In summary, mechanical milling can produce high purity tungsten trioxide powder. But the milling conditions have a great influence on the particle size. The ball milling time and the ratio of pellet to particle size tend to be stable. It is better to prolong the time blindly and increase the ball size rather than the thinning effect. On the contrary, it will increase the introduction of impurities.

评论

发表评论