Wolframite and Scheelite Mixed Flotation -- Shizhuyuan Method

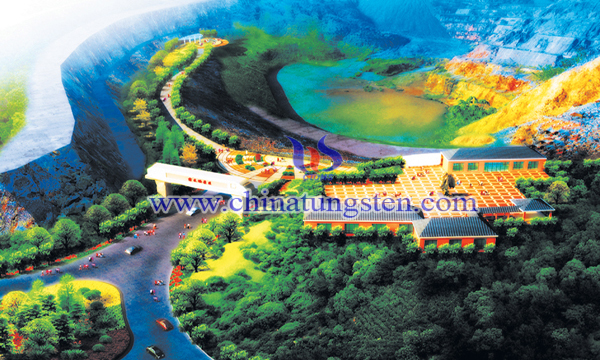

Hunan Shizhuyuan Tungsten Polymetallic Mining Area is a large deposit with a variety of minerals, with up to 143 kinds of mineral varieties.

It is mainly composed of tungsten, tin, bismuth and molybdenum, and is rich in fluorite, copper, lead and zinc , sulfur, iron, gold, silver, beryllium, niobium, tantalum and other minerals, the economic value is difficult to estimate.

Shizhuyuan ore mineral embedded in the complex size of the mineral industry is recognized by the most difficult mineral processing. The ratio of wolframite and scheelite ore is 3:7, and a lot of fluorite, molybdenum and bismuth are associated with it. In the early stage, shizhuyuan using the traditional method of heating and flotation to 733 oxidation of paraffin soap as a collector, the total recovery of tungsten ore is only 40-50%, a large number of waste of resources to make the economic benefits of the mine hesitant.

In order to get rid of the waste of tungsten resources at an early date, at the beginning of this century, Guangzhou Nonferrous Metals Research Institute, Beijing Institute of mining and Changsha Nonferrous Metallurgy Design Institute and other units jointly tackle key problems, based on the GY chelating collector, a new method of mineral processing, such as molybdenum bismuth and other floatable and bismuth sulfur, and CF-GY combined with the new process of flotation tungsten, a new method of dressing combined with the new technology of CF-GY combined method known as "floating wolfram, shizhuyuan method".

The method is based on the heating flotation method, using highly selective chelating collector CF and GYB mixed flotation wolframite and scheelite and recycle of wolframite slime, a set of processes can realize the difficult technical problems of wolframite and scheelite flotation and difficult separation by flotation of calcium containing minerals. A new flotation process of molybdenum bismuth and other floatable - bismuth sulfur floating - combination inhibitor molybdenum bismuth separation - oxidation bismuth sulfur separation was developed by separating molybdenum, bismuth and so on; Tungsten coarse concentrate combined with sodium sulfide and water glass heating cleaning process, a new process for fluorite flotation by high intensity magnetic separation with combined inhibitors and selective collectors, it provides technical guarantee for the exploitation and utilization of fluorite resources in ores.

The ore of shizhuyuan polymetallic mine in WO3 containing 0.25%-0.45%, belong to low grade complex ore. The industrial test showed that the shizhuyuan tungsten dressing method, the recovery rate can be increased to about 77.70%, nearly 30% increase over the old flotation method, do not underestimate this 30%, for the enterprise, it was tens of millions of economic income.

The recycle rate of tungsten has been greatly improved, and the cost of ore dressing has decreased because of the “shizhuyuan” method, it is a revolutionary breakthrough in the beneficiation technology of tungsten, tin, molybdenum and bismuth in China. It has set a benchmark for many low efficiency mines and pointed out the road.

If you have any inquiry of tungsten, please feel free to contact us:

Tel.: +86 592 5129696/+86 592 5129595

Fax: +86 592 5129797

Scan QR code of Chinatungsten Wechat platform to follow up the daily latest price and market of tungsten, molybdenum and rare earth.

评论

发表评论