Ultrafine Tungsten Powder Preparation -- Hydrogen Reduction Method (3)

The hydrogen reduction process of tungsten oxide, is a very complex physical and chemical processes, including chemical conversion, phase transformation, solid diffusion and so on.

The process generally is: tungsten oxide, hydrogen reduction, sifting, blending, tungsten powder. Different tungsten oxide reduction process of reaction pathways, the reaction speed is different, in general, the reduction reaction pathway and to avoid the simple single reaction generated in the process of WO2 is beneficial to preparing fine tungsten powder uniformly. That is to say, the tungsten powder obtained by route WO2.9 → W or WO2.72 → W would be more satisfactory.

Hydrogen reduction of tungsten oxide is usually carried out in a multiple tube furnace or a rotary furnace. Multiple tube reduction furnace has 3 to 5 containers used for loading, use artificial way in accordance with the order of loading and unloading material, excessive hydrogen or against the tungsten material movement direction into the tubular reduction furnace and material reaction; The rotary reduction furnace is heated uniformly by constant rotation so that the material is in a dynamic powder flow.

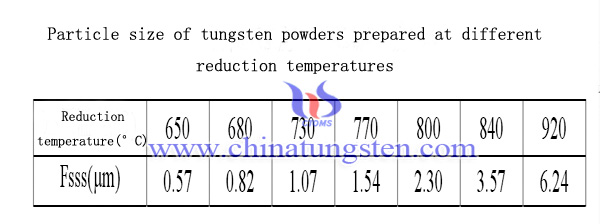

In the reduction furnace, tungsten powder particle size reduction temperature can be roughly divided into two sections: in the low temperature (<800 °C), the rate of change of particle size with temperature (i.e., slope of tangent) is more gentle; at high temperature (>800 °C), particle size begins to fluctuate with temperature. When the temperature is high, the reduction reaction will go through the intermediate stage of WO2. WO2 can be easily sintered and recrystallized at high temperature, which results in the thickening of tungsten powder. So in the actual production, taking into account the low temperature reduction reaction speed is slow, affects the production efficiency, often use the method of ladder type heating. That is, the temperature of the latter temperature zone of the reduction furnace is higher than the previous one. If the temperature gradient is too large, the particle size distribution will become wider. This is also why the use of multiple tube equipment is more than the rotary furnace equipment.

In addition, tungsten oxides form WO2(OH)2 with water vapor, when the compound has a large vapor pressure at 500~700 °C, it will be reduced to H2 on the reduction product, thereby thickening the particles. In addition, the water vapor will oxidize the tungsten powder, and the oxidized products will be reduced on the surface of the tungsten oxide, which will thicken the particles. Therefore, to obtain tungsten powder with finer particle size, more H2 flow is needed than usual to remove water vapor to prevent the formation of WO2.

In the process of producing ultrafine tungsten powder, the key is to control the suitable temperature and reduce the formation of volatile hydrated tungsten oxide (WO2(OH)2), and restrain the process of chemical vapor migration.

If you have any inquiry of tungsten, please feel free to contact us:

Tel.: +86 592 5129696/+86 592 5129595

Fax: +86 592 5129797

Scan QR code of Chinatungsten Wechat platform to follow up the daily latest price and market of tungsten, molybdenum and rare earth.

评论

发表评论