Blue Tungsten Oxide and Purple Tungsten Oxide

The performance of tungsten oxide materials will directly affect the reduction behavior of tungsten powder and the final product performance.

Therefore, on which material is most suitable for the production of ultrafine tungsten powder has been the subject of much attention in material science workers.

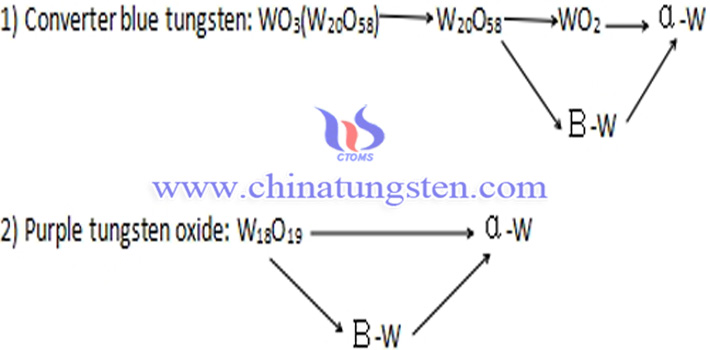

Blue tungsten oxide and purple tungsten oxide is the main raw material for production of ultrafine tungsten powder, blue tungsten oxide originated in the last century 70's, mainly WO2.90, W20O58 and ammonium tungsten bronze (ATB) mixture. Purple Tungsten oxide is a kind of tungsten oxide product developed in recent years in China. Its phase composition is WO2.72 or W18O49.

Blue tungsten oxide is present through hydrogen reduction of raw materials prepared by tungsten powder is the most widely used, as long as the conditions of low temperature, dry hydrogen, high hydrogen flow, thin material layer, producing ultrafine tungsten powder method can restore the blue tungsten oxide by hydrogen.

Purple tungsten oxide is developed in recent years, because of its unique properties, it has shown its superiority in the production of ultrafine tungsten powder.

At present, in the production of ultrafine tungsten powder, purple tungsten oxide and blue tungsten oxide two kinds of raw materials are used simultaneously. Therefore, some scholars have compared the two kinds of raw materials and conducted hydrogen reduction experiments under the same process conditions. The difference of particle size and uniformity of tungsten powder after reduction has been compared. The following conclusions are obtained by comparison:

1. Both blue tungsten oxide and purple tungsten oxide can be used to produce ultrafine tungsten powder under certain reduction conditions. But the excessively high hydrogen flow of the blue tungsten and the excess material will lead to an increase in cost.

2. Purple tungsten oxide due to its special pore structure, the water vapor can be rapidly discharged from the reducing atmosphere to produce a fine and uniform tungsten powder, and the particle size of tungsten powder is affected by the loading volume and the hydrogen flow rate.

3. Purple tungsten oxide generating hydrogen gas in drying without going through the intermediate stage of reducing WO2, thereby obtaining a fine and uniform tungsten powder.

To sum up, the preparation of ultrafine tungsten powder from purple tungsten oxide has more advantages than blue tungsten oxide.

If you have any inquiry of tungsten oxide, please feel free to contact us:

Tel.: +86 592 5129696 +86 592 5129595

Fax: +86 592 5129797

评论

发表评论