Tungsten Oxide in Inverted Polymer Solar Cell

Interest in solar cells to capture sunlight and generate electricity is increasing due to oil energy crisis and rising concerns over global climate change. Inorganic solar cells can yield high power conversion efficiency but the expensive fabrication process makes them infeasible in common use. Instead, polymer solar cells PSCs are a good candidate because semiconducting polymers can be dissolved in common solvents and printed like inks so that economical roll-in-roll fabrication process can be realized. The photoactive layer composed of electron donating and accepting materials absorbs light and generates excitons. Then electrons and holes can be efficiently separated from each other due to the nanometer-scale interpenetrating network of electron donor and acceptor within the whole photoactive layer.3 However, a simple structure that sandwiched the photoactive layer between two electrodes anode and cathode is not perfect enough. The low efficiency of charge collection at the interface between the photoactive layer and electrodes results in poor performance of PSCs.4 In order to solve this problem, interfacial layers, such as a combination of poly-ethylenedioxythiophene: polystyrenesulfonate and lithium fluoride LiF, are commonly introduced between the active layer and electrodes to improve charge carrier collection and to enhance the open-circuit voltage.

Nevertheless, PEDOT: PSS has been demonstrated to have a side effect on the performance of PSCs due to its corrosion to indium tin oxide ITO and electrical inhomogeneities. In order to overcome this problem, one might simply introduce interfacial layer materials to improve the performance of PSCs. Recently, molybdenum oxide MoO3, vanadium oxide V2O5, and nickel oxide NiO have been demonstrated to effectively substitute PEDOT:PSS as the anodic buffer layer in PSCs. An alternative approach is to reverse the device architecture and hence to form inverted PSCs, in which MoO3 and V2O5 were usually inserted between the active layer and top electrode.

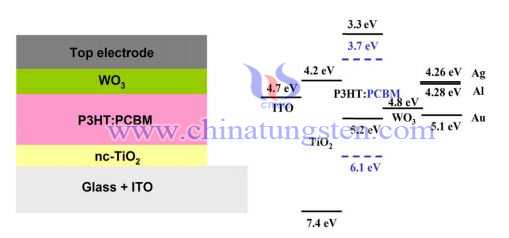

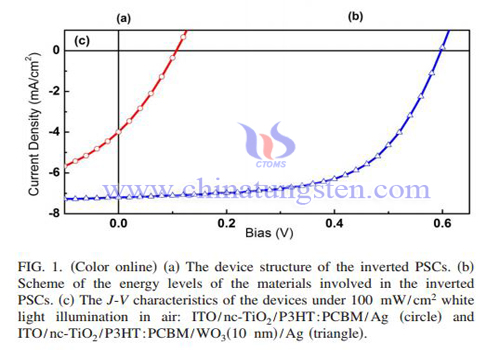

In this letter, we introduce a low-cost, nontoxitoxic, and easily evaporable tungsten oxide WO3 as a hole extraction layer in inverted PSCs with nano crystalline titanium dioxide nc-TiO2 as an electron selective layer. The device architecture is shown schematically in Fig. 1 a. and the energy level diagrams of different materials used in the device fabrication are shown in Fig. 1b. Meanwhile, transparent inverted PSCs are fabricated with thermally evaporable Ag13 nm/WO340 nm as a transparent anode when introducing a 10 nm WO3 buffer layer. After a cleaning step, TiO2-sol was spin coated on ITO-coated glass substrates at 3000 rpm. Then the samples were moved to a muffle furnace and annealed at 450 °C for 2 h. After annealing treatment, nc-TiO2 was formed. In this letter, poly3-hexylthiophene P3HT Rieke Metals was used as electron donor material, and -phenyl C61 butyric acid methyl ester PCBM Solenne BV was used as electron acceptor material. The mixed chlorobenzene solution composing of P3HT 10 mg/ml and PCBM 8 mg/ml was then spin coated on top of the nc-TiO2 layer at 700 rpm in ambient air. Then the samples were heated in low vacuum oven at approximately 150 °C for 10 min. Subsequently, the samples were pumped down in vacuum 10−3 Pa. Finally WO3 and 60 nm top electrode Ag, Au, and Al were thermally evaporated in sequence. The active area of the device was about 0.064 cm2 .

In summary, we have explored the use of WO3 in inverted polymer solar cells. Due to the high work function 4.8 eV, WO3 efficiently extracts holes and suppresses electrons from the active layer. The thicknesses of WO3 and different top metal electrodes on device performances are also investigated. Transparent inverted PSCs are fabricated with Ag13 nm/WO3 40 nm as a transparent top electrode when introducing a 10 nm WO3 buffer layer, which have the potential to realize a multiple device structure to absorb more solar photons by the multiple photoactive layers to achieve high device performance.

If you have any other question or inquiry of tungsten oxide, please feel free to contact us through the following methods:

Tel.: +86 592 5129696/86 592 5129595

Fax: +86 592 5129797

评论

发表评论